Hand Laying Track

As part of the next stage of my testing before the big layout build, I want to lay a bunch of track by hand to see how much work it entails, and evaluate it from cost, performance, and appearance standards.

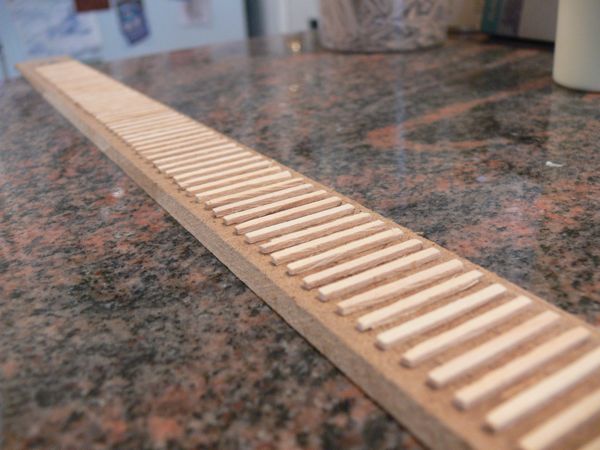

First up though, is a small mini-test section. Here's what I've gotten done so far.

|

Materials/Tools in this picture

|

|

Ties go in the jig. |

|

and a piece of painters blue tape is applied, than the whole thing gets pulled carefully out. |

|

just a little (as you can see) yellow carpenter's glue is applied |

|

And then the ties go down. After the glue had set for an hour, I carefully pulled the tape off. |

|

Ok, this is looking pretty good so far. |

|

Some people recommend dipping the ties in advance, others say to do so after they are glued down. I thought I would try the latter. This picture shows some of the ties after just one coat of the Minwax stain. Materials added:

|

So I'm not satisfied with the tie color, I think it's too black.

I removed one tie to show myself where the "break" is - the first set I'm leaving untouched, the second set I want to drybrush brown over.

The next set of ties will be stained with a black/brown mix. I want a bunch of sections to determine what looks best.

>> Posts index

Navigation

Journals/Blogs

Recent Blog posts:

Comments

Success with MDF

Well, there is alwasy at least one success story to offest the tales of failure. It's great that you have had such success with MDF in your modeling but your success will not change my opinion of MDF much. :o)

I'll be using masonite for spline this time around. Other than that I intend to use as much real wood as I can.

The great thing about MDF is that is machines very well and is is less expensive.

That's about where my list of pros ends and the cons begin. ;o)

Now that's just my opinion. Individual results may vary as Nick has pointed out.

Real Wood

Well Blue,

I can't argue with you on that, nothing beats real wood, nothing. You can't go wrong with that !

Imitations is imitation and wood has been around since the beginning of time, maybe before that .

Nick Biangel

USMC

use homasote

Homasote takes spikes easily yet holds them fast. I've always used Homabed (brand name for a manufactured roadbed made from homasote) since the 1970s and have been very pleased with the product.

Mark

Better now than later

Better to find out now on a little test piece than when you've started to build a whole layout with those materials :)

Chris van der Heide

My Algoma Central Modelling Blog

Canadian Freight Car Gallery

CPR Sudbury Division (Waterloo Region Model Railway Club)

Failing isn't failure

"I'm not a failure. I found 10,000 ideas that didn't work."

Cork is really good;

Cork is really good; underlying plywood is hard but it holds really well. The layouts at La Mesa seem to use wood under all their tracks, if I remember right.

Your ballasted section looks good, but the ballast needs to continue over and down the shoulders to get the full profile complete.

---------------------------------------------------------------------------------------------------------

Benny's Index or Somewhere Chasing Rabbits

At the club we just spike to

At the club we just spike to ties laid directly on the plywood or pine spline.

Chris van der Heide

My Algoma Central Modelling Blog

Canadian Freight Car Gallery

CPR Sudbury Division (Waterloo Region Model Railway Club)

Roadbed Materials

I've used MDF in other hobbies for scenery bases, and the like, and haven't seen this kind of warping. And that's with using a water/glue mix to hold down scenery items. However in those cases the items were primed first, it could be that the primer coat sealed the MDF.

More frustrating was the fact that I was able to push a spike into the MDF easily - otherwise I wouldn't have pursued this method. But it was a different spike, and there were not ties involved; not sure how that makes a difference but it seems to have.

Remembering my goal of trying to achieve as stable (ie no movement from humidity), using a soft pine for the subroad is what I have been trying to avoid. However, it seems that handlaying is working in direct opposition to that design.

From what I've read, cork does not hold spike securely enough for handlaying, so I have ruled that out, likewise with the foam based products.

The homoroad looks good, but I'm put off by the price. Simply said, I'd need to mail order, and I'm not too eager to dive into that product without seeing it first. The homoroad seems to run about one dollar a linear foot in cost; a single sheet of 1/2 inch homosote at our home depot is $14. Once our rain stops, I guess it's time to don a mask and fire up the table saw.

Home Made Homabed

I seem to recall posting this link for you before, scarpia, but just in case I did not:

http://www.housatonicrr.com/DIY_Roadbed.htm

Chris

“If you carry your childhood with you, you never become older.” My modest progress Blog

MDF?

That sure doesn't sound like MDF to me. There used to be an inferior product that was similar in makeup that we called "particle board", I could see a spike being pushed into that, but not into MDF. It now occurs to me that there are various grades of MDF that can differ in hardness. Perhaps the MDF you used before was a lower grade?