Benchwork - Roadbed

Pembroke II: Engine House Ground

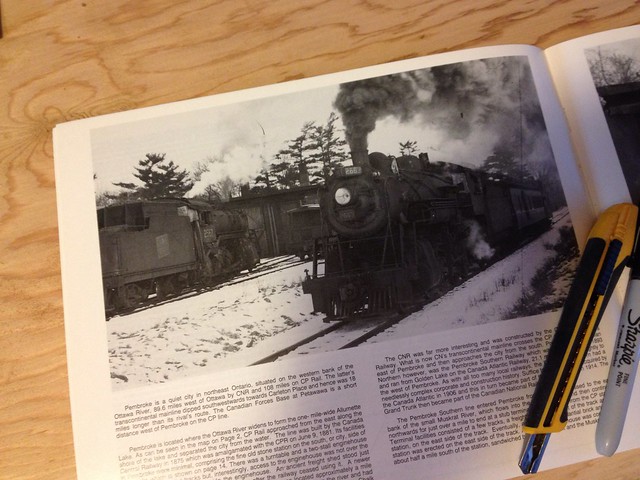

One of the challenges with building Pembroke in a house that is still under renovation is that some of my research material is buried. While the basement has been largely finished since before Christmas -- don't ask me about baseboards and that closet door -- there are still shelves and various cabinets to construct. So, I've been relying mostly on information on my Canada Atlantic research website and on my Flickr stream (mostly not public). One critical photo lives only in a BRMNA book, and it shows the relationship between the mainline and the area around the engine house.

Richlawn RR V2 - Benchwork continues

For some benchwork is boring but I enjoy it - to a point. There's nothing new or innovative in what I'm doing but I'll continue posting so you can follow along.

Will it Warp?

Will this support plan wind up warping later?

I'm in a climate controlled basement. Temps do vary by 10 degrees or so summer to winter but humidity level is relatively constant. Plywood deck is 3/4 inch birch cabinet grade. I had to modify my support structure so I now have the upper deck here supported on the sides of 1x2 strips ripped from plywood. I needed the extra height for the deck, and I new with a 24 inch wide section that the upper deck needed some lateral support under it or it would sag.

(Not) Ballasting

Since I'm not a fan of ballasting, on my last layout I sanded down cork roadbed to a more proto profile and left it unballasted. There was enough color variation among the little bits in the cork that it looked ok to me.

I've started a new shelf switcher and don't want to bother with sanding cork again, so I'll probably use thin cork sheet (roll) for roadbed. The color of the sheet is not as realistic looking to me as the cork roadbed though.

Opinions please on using 2" foam as the sub-roadbed on my benchwork

Elsewhere on this site there has been some discussion on using foam board and sound issues. I am planning on using 2" extruded foam board as the top for my wood bench work without using any plywood. The foam would also serve as my sub-roadbed on which I would use adhesive caulk with either traditional cork or the WS foam roadbed. I thought that I would like to use the foam for the bench top because of how easy it would be to sculpt the land forms.

Construction of the Second Spline Helix & Hidden Staging Area - Progress Update

SPLINE HELIX UPDATE: Back a few months ago, someone asked about how engines and cars would be prevented from falling off of the helix. Originally, I thought about using cardboard or hardboard strips. However, their use would have reduced the narrow opening between helix turns so I looked around the garage and found some left over screening (nylon or fiberglass). I also bought some white poster board from a local office supply.

Apparently I didn't get the Memo

Must have missed the memo about the "sound board" effect of 2 in Styrofoam being much more noticeable than that of 1/2 in plywood - especially with the track laid directly on the foam.

Although I don't find it particularly objectionable, it is readily apparent when the train leaves the part of the layout with plywood subroadbed and moves onto the Styrofoam section. So, does anyone have any suggestions on how to attenuate this effect short of tearing up the track and relaying it on cork roadbed on top of the foam?

If not, I guess I can live with it.

>> Posts index

Navigation

Journals/Blogs

Recent Blog posts: